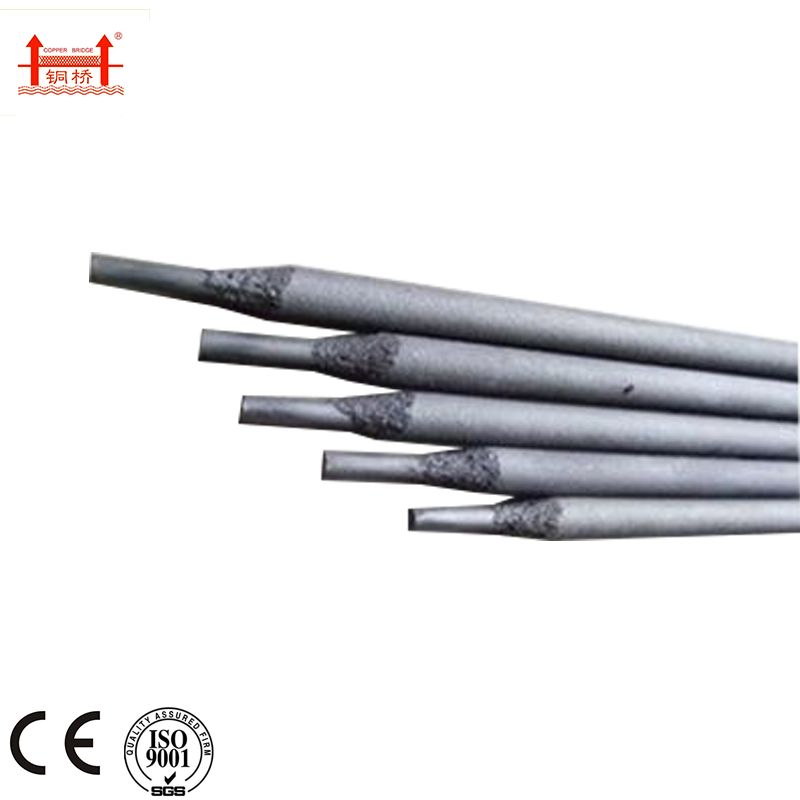

Stainless hlau Electrodes CB-A102

Daim ntawv ceeb toom siv stainless hlau electrode

1. chromium stainless hlau muaj qee yam corrosion kuj (oxidizing acid, organic acid, cavitation), kub tsis kam thiab hnav tsis kam.Feem ntau siv rau hauv cov nroj tsuag fais fab, tshuaj, roj av thiab lwm yam khoom siv.Chromium stainless hlau tsis zoo weldability, yuav tsum tau them sai sai rau cov txheej txheem vuam, kev kho cua sov thiab xaiv cov electrode tsim nyog.

2. CR-13 stainless hlau muaj hardness siab dua tom qab vuam thiab yooj yim rau kev tawg.Yog tias tib hom chromium stainless hlau electrode (G202, G207) siv rau vuam, nws yuav tsum tau preheated saum 300 ° C thiab txias txog 700 ° C tom qab vuam.Yog tias qhov vuam tsis tuaj yeem ua tiav tom qab vuam kev kho cua sov, ces qhov kev xaiv ntawm chromium-nickel stainless hlau electrode (A107, A207).

3. Chromium 17 stainless hlau, txhawm rau txhim kho corrosion kuj thiab weldability thiab nce qhov tsim nyog ntawm cov khoom ruaj khov xws li Ti, Nb, Mo, thiab lwm yam, weldability zoo dua li chromium 13 stainless hlau.Thaum tib hom chromium stainless hlau electrode (G302, G307) siv, nws yuav tsum tau preheated saum 200 ° C thiab tempered ib ncig ntawm 800 ° C tom qab vuam.Yog tias qhov vuam tsis tuaj yeem kho cua sov, ces qhov kev xaiv ntawm chromium-nickel stainless hlau electrode (A107, A207).CR-NI stainless hlau electrode muaj corrosion kuj zoo thiab oxidation tsis kam, dav siv nyob rau hauv chemical kev lag luam, chiv, roj av, kev kho mob machinery manufacturing.

4. 0 thiab hauv qab no tuaj yeem siv rau txhua txoj haujlwm vuam.

5.0 thiab saum toj no rau kev sib tw tiaj tus thiab fillet vuam.

6. Chromium-nickel stainless hlau txheej muaj titanium-calcium hom thiab tsis tshua muaj hydrogen hom.Calcium titanate hom tuaj yeem siv rau hauv AC thiab DC, tab sis qhov nkag mus ntawm qhov ntiav AC vuam, thaum yooj yim rau xim liab, yog li siv DC fais fab mov.Txoj kab uas hla

7. Cov electrode yuav tsum tau qhuav, hom titanium-calcium yuav tsum tau qhuav ntawm 150 ° C rau 1 teev, thiab hom hydrogen tsawg yuav tsum tau qhuav ntawm 200 ° C mus rau 250 ° C rau 1 teev (tsis txhob rov ziab dua, txwv tsis pub. txheej txheej yog yooj yim tawg thiab tev tawm), tiv thaiv cov electrode txheej nplaum cov roj thiab lwm yam av, thiaj li tsis ua kom cov pa roj carbon ntsiab lus ntawm vuam thiab cuam tshuam qhov zoo ntawm vuam.

8. Txhawm rau tiv thaiv corrosion ntawm lub qhov muag los ntawm cua sov, qhov vuam tam sim no yuav tsum tsis txhob loj dhau, tsawg dua cov pa roj carbon steel electrode txog 20%, ARC yuav tsum tsis txhob ntev dhau, txias ceev ntawm cov khaubncaws sab nraud povtseg, kom cov hlaws nqaim yog tsim nyog. .

| Qauv | GB | AWS | Txoj kab uas hla (mm) | Hom Txheej Txheej | Tam sim no | Siv |

| Qauv: CB-A102 | E308-16 | E308-16 | 2.5-5.0 Nws | Hom txiv qaub-titania | DC | Siv rau vuam corrosion-resistant 0cR19Ni9 thiab 0Cr19Ni11Ti stainless hlau cov qauv hauv qab 300︒C |

Chemical Composition ntawm Deposited Hlau

| Chemical Composition ntawm Deposited Hlau (%) | ||||||||

| C | Mn | Si | S | P | Cu | Ni | Mo | Cr |

| ≤ 0.08 | 0.5-2.5 hli | ≤0.90 | ≤ 0.030 | ≤ 0.040 | ≤ 0.75 | 9.0-11.0 Nws | ≤ 0.75 | 18.0-21.0 Nws |

Mechanical Properties of Deposited Hlau

| Mechanical Properties of Deposited Hlau | |

| Rm (Mpa) | A(%) |

| ≥550 | ≥35 |

Ntim

Peb lub Hoobkas

Exhibition

Peb Daim Ntawv Pov Thawj